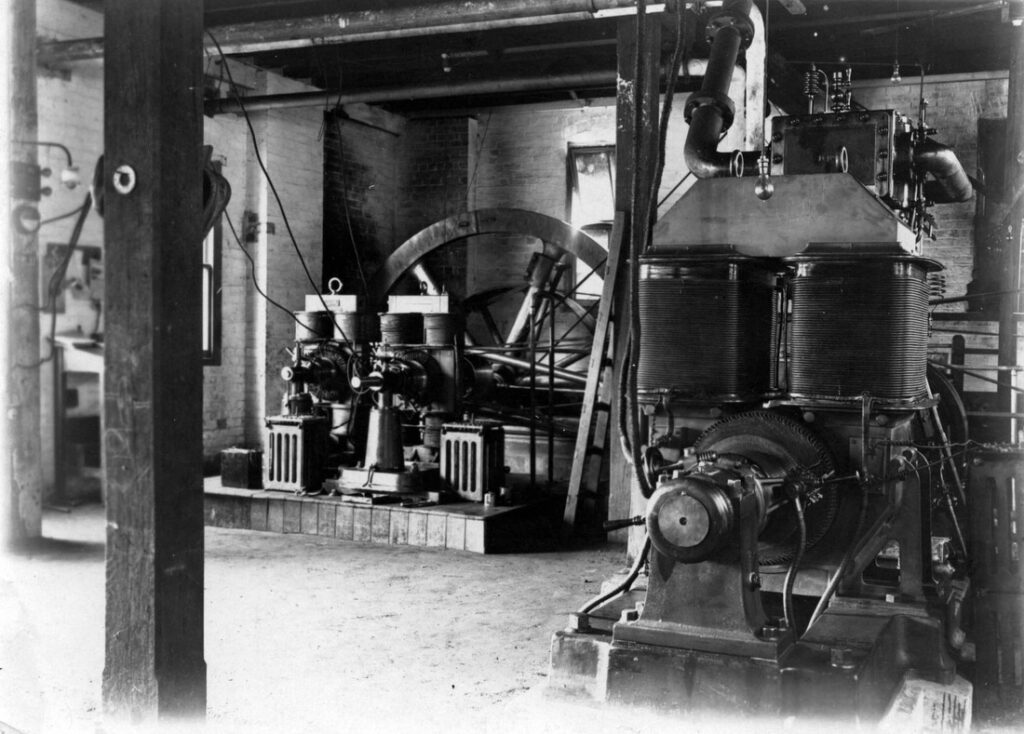

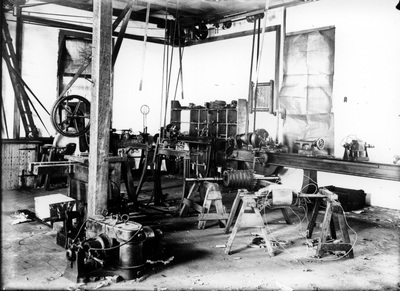

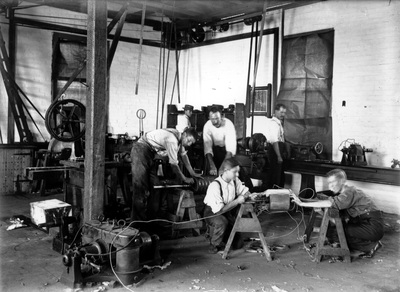

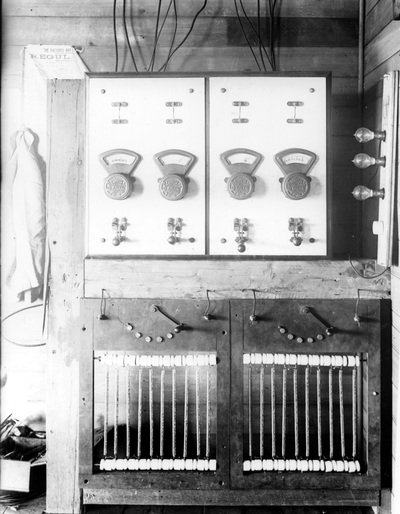

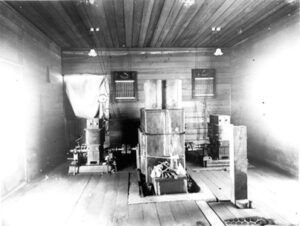

Interior of Thargomindah’s early Hydro-Electric Powerhouse The switchboard and meters on the left were installed by Edward Barton’s Brisbane company, the Brisbane Electric Supply Company (BESCo)

1892

The small western town of Thargomindah was reported as being the first town in Queensland to establish, rather than demonstrate, electric street lighting. Electricity for the street lights was generated by a small steam engine in early 1892. The plant belonged to Mr. Paterson, a local sawmill owner. Another local man named Simpson erected the machinery. However, on 24 January, 1893 the Queenslander published a report implying that Thargomindah was ‘lit by electricity for the first time last night’. Regardless of the slightly conflicting reports relating to the initial appearance of electric street lighting in Thargomindah, the town can still claim to be the first in Queensland to have an established electrically-powered street lighting system. Thargomindah’s Hydro-Electric Powerhouse continued operating until 1951 when it was replaced by a diesel engine driven generator. 1892

In 1892 Barton, White and Co. were given the responsibility of laying the underground cables for a new section of the Parliament buildings in Brisbane, which planned to have 130 lights. The company also installed the inside wiring. Trackson’s supplied the light fittings. A report in the Brisbane Courier in June 1892 carried a description of the electric lighting trial in the new section. It stated that the ‘lights in the dining and smoking rooms were very brilliant…’ in comparison to the older type of lights. The report explained that the power for the lights was ‘supplied by two 400-light dynamos of the Edison pattern’. The dynamos were positioned in the ‘electric room’ of the Government Printing Office. In the same year, Barton, White and Co. was also involved in lighting the Queensland Meat Export and Engineering Company’s works in Brisbane.

The Rockhampton Gas & Coke Company commenced its electricity undertaking in 1892. When it closed down, Rockhampton City Council took over as the supply authority in August 1924.

1896

The first Government legislation for the control of electricity supply in Queensland was introduced under the Electric Light and Power Act of 1896. The Act provided for any person, local authority or company to apply for an Order-in-Council, which would authorise the supply of electricity in a specifically-stated area. The Orders set out the perimeters within which the licensed individual, authority or company could operate, including their powers, duties and liabilities. It was a requirement that applicants for Orders-in-Council must advertise their intentions and, when not a local authority, inform the authority in the area of the application. Generally, the consent of the local authority was required before an application was granted. Furthermore, the legislation allowed for multiple applications for the same area and granted local authorities the right to acquire an undertaking in its area through compulsory purchase after a period of 42 years or earlier, or subsequent 10-year periods, depending on the stipulations in the Order. It was a complicated set of rules and before passing, the Act was put through scrutiny and debate. However, by ensuring that Orders-in-Council were applied for, and complied with, the Postmaster–General declared

The first Order-in-Council was issued to Brisbane Electric Supply Company (BESCo) in 1897 and covered a small part of North Brisbane. Apart from BESCo, companies in Charters Towers and Rockhampton were among the first few to be granted Orders-in-Council. A private company in Charters Towers was issued an Order-in-Council in the same year as BESCo, 1897.

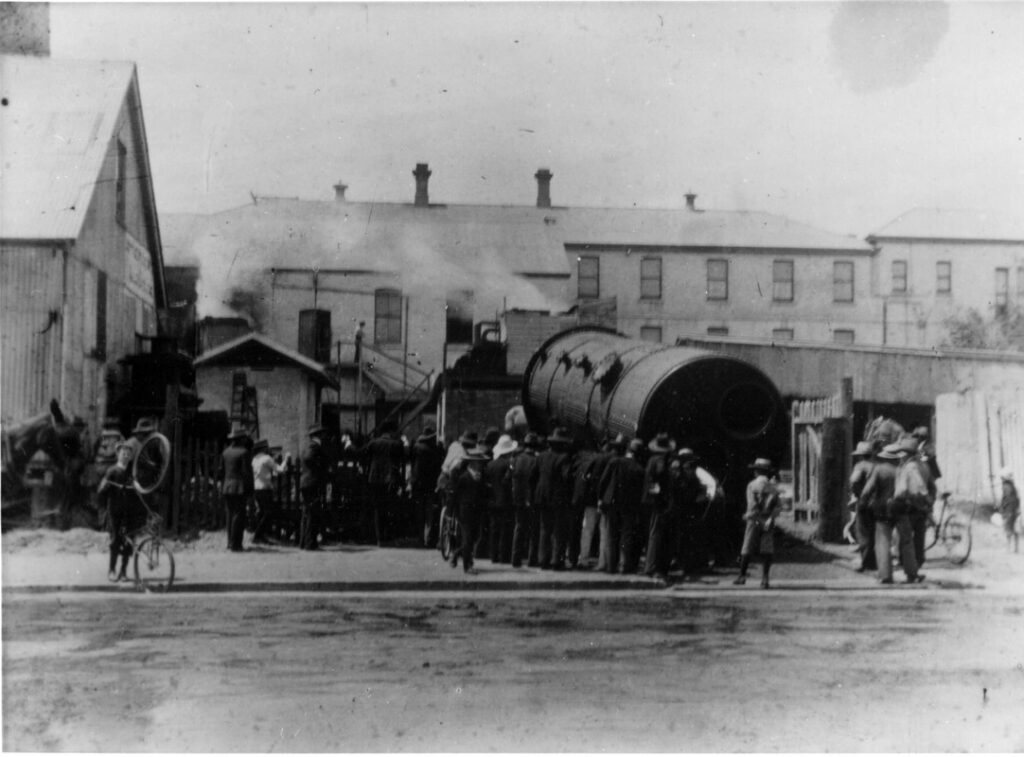

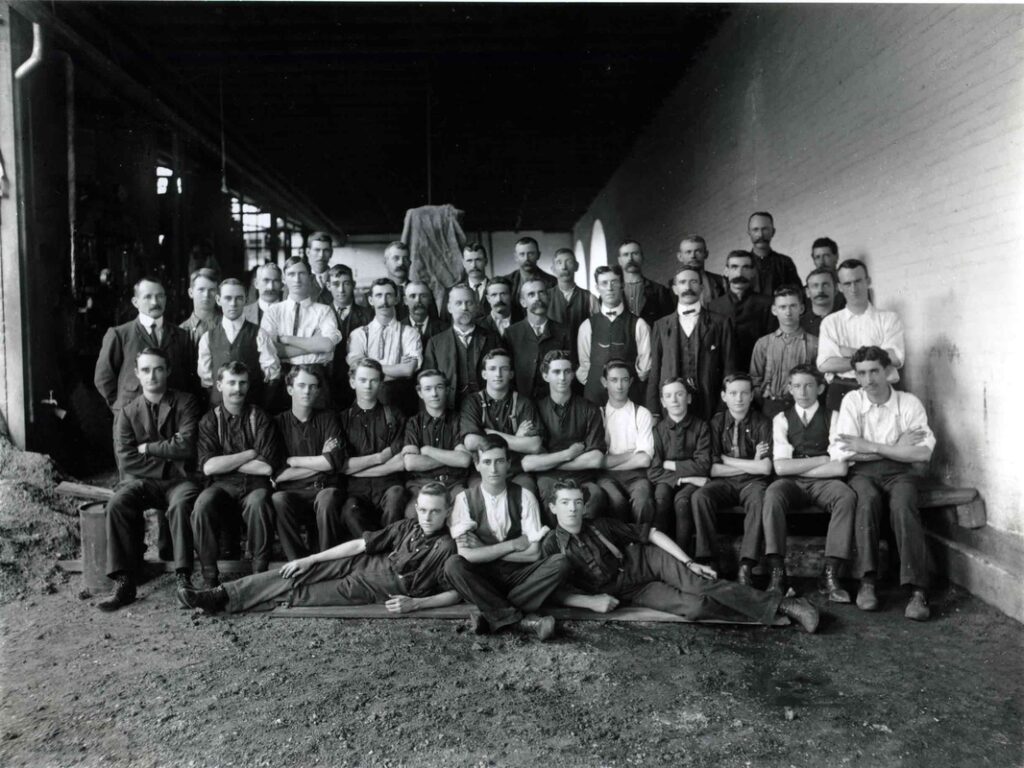

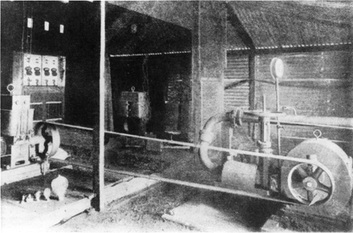

Following an amendment to the Tramways Act (1882) in 1890, which included an authorisation allowing a company to sell its undertaking, the Brisbane Tramways Company Ltd. was formed in 1895. The new company took over the responsibility of the trams in Brisbane and went ahead with its plans to convert the trams to operate on electricity. Mr. J.S. Badger from the USA was called on to supervise the work. He was appointed Manager and later became General Manager, then Managing Director. He remained with the Tramways for many years. The first electric tramway was officially opened on 21 June 1897 and the electric tram service through Queen Street began on 3 July 1897. The Brisbane Tramways Company engaged the Tramways Construction Company Limited, a London firm, to build its first powerhouse in Countess Street, Brisbane. Smaller powerhouses were built subsequently in Light Street and Logan Road. The first section of the powerhouse in Countess Street was completed in 1896 and commissioned in 1897.

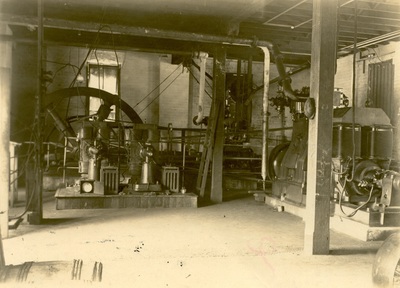

The plant comprised three Robey cross-compound horizontal, non-condensing steam engines, each belt driving a 300 kW, 550-volt direct current (DC) generator. Each belt was ninety feet long and three feet wide. There were four hand-fed boilers working at 150 pounds per square inch of pressure to provide steam to the engines.

1899: Ann Street Powerhouse

Edward Barton made a decision to relocate from his Edison Lane powerhouse to new premises in Ann Street in 1899. The Ann Street Powerhouse was larger and featured a higher stack, which reduced some of the earlier smoke-related problems. Inside the powerhouse in 1899 there was a horizontal slow-speed steam engine driving two Crompton open-type D.C. dynamos. A Robey high-speed vertical steam engine directly-coupled to a 50 kW dynamo arrived in early 1900 and a Brush vertical steam engine in 1901. Progressively from 1901 to 1909 the plant was extended and upgraded with Parsons steam turbines.